When I meet Franz Schmidt, we go for a walk. As we wander through Oslo – from our meeting place at the arts academy Kunsthøgskolen i Oslo to the building complex Prinds Christian Augusts Minde (Prindsen) to the contemporary art gallery Oslo Kunstforening – Schmidt tells me about the past: the histories of the city, neighbourhoods, buildings, Norwegian textile industry (from its stellar rise to its partial demise), power looms and, of course, his own work, which led to this project. We are wandering not only through Oslo but also through a kind of chronology. In Schmidt’s hands – or should I say “feet”? – space becomes time.

This particular connection between space and time – whereby movement fuses with recollection – has been documented in Frances A. Yates’s classic study of the history of mnemonic techniques The Art of Memory (1966). That history begins with the Greek poet Simonides of Ceos (c. 556 – 468 BC) who inadvertently discovered the first art of memory when he was invited to recite at a nobleman‘s banquet in Ancient Thessaly. As Simonides went outside to meet messengers, the hall collapsed behind him, crushing all of the guests to death. Yet Simonides was able to identify the disfigured victims for their family members because he recalled precisely where each guest had been sitting at the banquet table. His impromptu solution developed into the elaborate, venerated art of “memory loci” (memory places): positioning evocative images of what one wanted to recall within the architecture of a specific building. Any one building could be used in the imagination to remember not only guests but also other elements: treatises, arguments, contracts, even poems. As one spoke, one would “walk” in one’s mind from one room to the next, from one image to the next, set up in each room like a flash card for total recall.

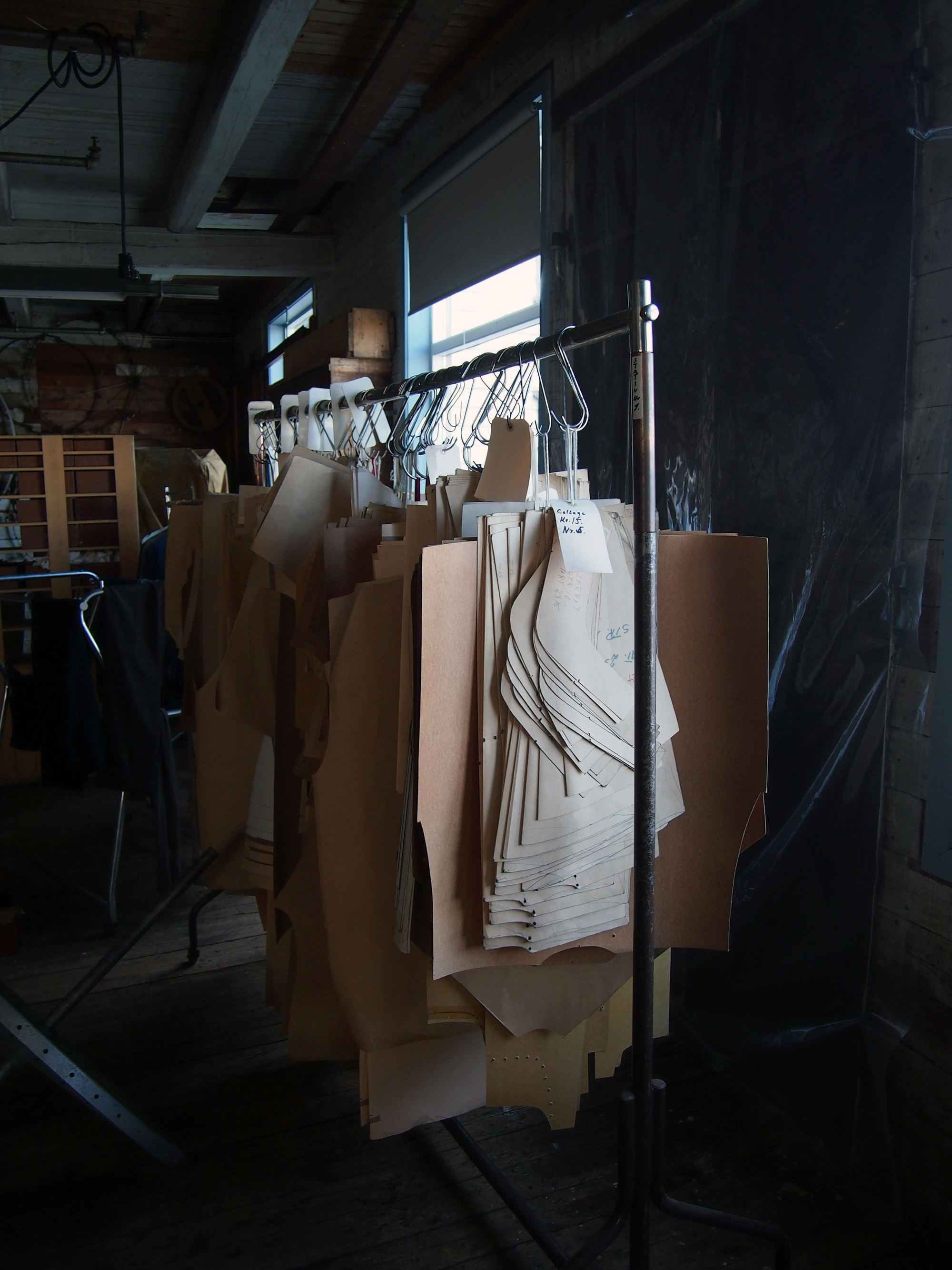

Like Simonides, Schmidt remembers real places, their pasts and the people who once inhabited them: crushed, not by a decrepit hall, but by economics and the sheer passage of time. He revisits buildings not just in his imagination but with his body, reminding me that the Oslo Kunstforening gallery is the oldest building in the city, just as we enter it. His texts about this project combine historical facts with strong sense perceptions: a warm intense spring, a dark shiny green moss, the feel of fabric in a textile sample book. What’s equally striking about the artist’s approach to the art of memory loci is his fusion of collective and individual histories. The arts academy is not only a former sail-cloth factory but also his alma mater. Prindsen was once not only home to visiting Danish kings, a reform house and an insane asylum but also part of Schmidt’s neighbourhood. As we inspect the rows of abandoned power looms inside the Prindsen complex, he explains how the inmates used them decades ago, followed many years later by one of his own colleagues, a former textile professor.

Unlike Simonides, Schmidt treats the art of memory loci as a means of reviving history: a two-way expansive path that runs from the past back to the present and into the future. Simonides could not revive the guests; Schmidt will make the Prindsen power looms run once again to produce textiles – just as he has done with the older machines he found at the traditional mill in Sjølingstad and with the older historical patterns he found at the modern mill Gudbrandsdalen Woollen Mill in Lillehammer.

Since the artist collaborates with the employees from the mills – and with fashion designers in and outside of Norway, looking for exceptional textiles – his individual work is a living past moving towards a collective future. Even in the Oslo Kunstforening gallery, Schmidt explains its history and then how he will set up his own upcoming exhibition, which recalls the various steps of his project, much like an itinerary: from Sjølingstad to Lillehammer to Oslo, from revamping the old power looms to making a suit from the cloth produced by them. As such, his project is not an immobile solitary monument but closer to a mobile, living network. All threads are connected with each other while leading to other people, places and pieces of fabric.

Schmidt’s art will always involve a double displacement since he has a holistic approach to the medium of textiles. On the one hand, the artist has moved from one town to the next to practice his art, from one mill to the next, from one loom to the next, from one cloth and suit to the next, because he was seeking not only to recall the past but also to revive it with others for the future – specifically at the Prindsen complex, which will become the active sum of his experiences. On the other hand, the artist cannot show the entire project in a classic white cube without a certain element of loss, precisely because he sought the full experience of textiles, not just one part of them, not just a photograph of them, not just one textile sample book, not just one fabric. But how to exhibit what is essentially an art of memory loci which occurs in specific mills and buildings in Norway and not just in the imagination? Schmidt decided to show, among other elements, a selection of archival materials, tools and souvenirs as well as meters of unique wool fabrics that he produced at the mills along with custom-made suits created with his fabrics. These exhibition pieces appear as the opposite of memento mori: not reminders of death but reminders that the textile traditions will live on.